Small I.D. Encapsulated O-Ring "Ovality" Design Tip

When you take a straight length of elastomer cord and FEP or PFA tubing, and form it into the shape of an o-ring, the mechanical stresses placed upon the elastomer dictates that the cross section will not remain ROUND, but become OVAL.

This is particularly relevant on encapsulated o-rings with small inside diameters on all cross sections; but especially on large cross sections. (Standard elastomeric o-rings are molded; therefore this condition is not present).

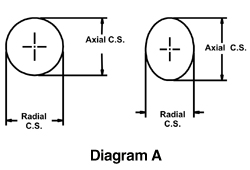

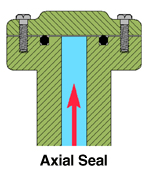

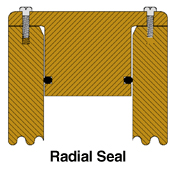

The o-ring cross section will become oval with an enlargement of the axial cross section; and a reduction in the cross section to the radial axis. (see diagram A) Without knowing the intended application (axial or radial seal), the only method that can be used to determine the correct dimension, is to apply the average cross section measurement from the axial AND the radial axis. The average of these 2 figures is used to determine if the o-ring is within manufacturing standards.

Design Recommendation Disclaimer:

Recommendations on application design and material selection are based upon available technical data and are offered as suggestions only. Each user should conduct evaluations to determine the suitability for his particular application. ROW, Inc. offers no express or implied warranties concerning the form, fit, or function of a product in any application.

![5[1] 5[1]](https://row-inc.com/hs-fs/hubfs/5%5B1%5D.png?width=200&height=200&name=5%5B1%5D.png)