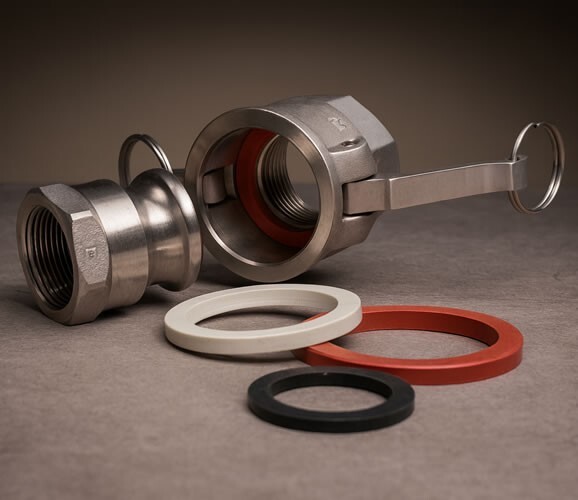

FEP Encapsulated Gaskets

ROW Incorporated

A Superior Seal for Chemical Applications

TFE-O-SIL® Silicone and Viton™ gaskets for cam lock couplings, encapsulated with FEP, are designed for use with practically all chemicals, even in the toughest corrosive environments. These gaskets combine the best qualities of two materials to form a superior seal: Elastomer as the core for resilience, and FEP on the outside for chemical resistance. Not an envelope gasket, the elastomeric core of every TFE-O-SIL® gasket is fully encased.

- Maintains reliable sealing across a broad temperature range, suitable for various industrial applications.

- Exceptional chemical resistance and durability in harsh environments with FEP Encapsulated Gaskets.

For part numbers of gaskets with Viton cores, substitute V for S. warning 1/2" size not available with Viton™core (only Silicone)

TFE-O-SIL® Features:

Excellent Chemical Resistance - FEP is chemically inert to almost all industrial chemicals and solvents, even at elevated temperatures and pressures

Resiliency - Elastomeric cores provide an assured tight seal

Wide Temperature Range - Continuous service temperatures from

-75°F (-60°C) to +400°F (+205°C) for FEP & silicone,

-15°F (-26°C) to +400°F (+205°C) for FEP & Viton™

Low Coefficient of Friction - Lubricious surface of FEP for easier gasket insertion

Nonstick Surface - Almost all substances release easily so cleanup is easier

Universal Seal - Handles practically any fluid. Eliminates matching the myriad elastomeric formulations with a specific requirement

Sanitary - Eliminates contamination associated with elastomeric gaskets.

White Gaskets - Introducing our latest line of TFE-O-SIL® Silicone core gaskets encapsulated with FEP. With their clean, sanitary appearance, our white gaskets are ideal for pharmaceutical applications. They are available in coupling sizes from 1/2" through 6" for temperature ranges from -75°F (-60°C) to +400°F (+205°C).

General Specifications

Core Materials

Silicone to ZZ-R-765 FDA Compliant - Ideal for pharmaceutical, food and beverage applications. (Available in red or white)

Viton™ - Ideal for overall chemical resistance.

Encapsulation

Solid .020 wall of virgin FEP made from resin which meets or exceeds the requirements of L-P-389A and ASTM-D-2116. FDA compliant & USP Class VI approved.

Sizes (Silicone Core Part Numbers Shown)

Typical Applications

TFE-O-SIL® Gaskets provide a superior seal for any bulk liquid transfer in manufacturing, distribution or storage.

Chemical Processing:

- From trucks to storage

- From storage to process areas

Cosmetic Industry:

- Transferring perfumes and oils

- Blending and batching oils and greases for soap

Petroleum Industry:

- Deliveries to service stations

- Oil canning

- Blending grease and oil

- Mixing oil additives

Paints & Dyes:

- Mixing color pigments

Pharmaceuticals:

- Blending raw materials

TFE-O-SIL® Gaskets for Bulk Liquid TransferRubber & Plastics:

- Blending liquids and resins

Printing & Marking Equipment:

- Hose connectors

Bulk Liquid Transfer:

- Mining slurries, agricultural chemicals, brewing

Engineering Assistance

Our engineering department is ready to assist you in solving your sealing problems. Samples may be provided for testing and evaluation.

*Orders are not refundable

![5[1] 5[1]](https://row-inc.com/hs-fs/hubfs/5%5B1%5D.png?width=200&height=200&name=5%5B1%5D.png)